New Large Capacity Twin Screw 500kg/hr Pet Food Machine,complete details about New Large Capacity Twin Screw 500kg/hr Pet Food Machine provided by New Large Capacity Twin Screw 500kg/hr Pet Food Machine in China.

.jpg)

Thermal Twin Benefits. Less costly energy source (vary input ratio of thermal to mechanical energy) – Lower SME. Lower wear costs compared to other twin screw systems. Less sticky products due to low shear. Ability to achieve higher meat and other slurry levels. More “natural” cooking (thermal energy) leads to development of new products.

.jpg)

Our single and twin screw extrusion machines excel in producing sheet, pellets, pipe, window profiles, vinyl siding, and profiles of wood and natural fiber plastic composites. We can also help with challenging projects that require complex system solutions for thermal sensitive compounds, complex shapes, or precision extrusions.

.jpg)

Co-rotating, intermeshing twin screw extruder: The co-rotating twin screw extruder is the most prevalent continuous mixing device in the world. Typical applications include masterbatch and compounding processes in which fillers, pigments, dyes and additives are homogeneously mixed into the plastic matrix.

.jpg)

Cases of pet food extruder visited by Mumbai customers +. Our Food Extruder Machine is a summary of many single and twin screw food extrusion equipment in food processing technical engineers who have more than ten years of experience. Loyal is single / two screw extruder manufacturers in food processing market in China .

Aug 14, 2023 · Advantages of Artificial Rice Extrusion Line: 1. Flexible: production of different shapes, textures, colors, integration of multiple soya proteins. 2. Productive: continuous processing, fast changeover times and easy cleaning. 3. Cost-effective: intensified processing, savings of raw materials, water and energy. 4.

Twin screw extruder tse 20/40 - applications in the food ind Cheap puffed corn ring snack food extruder machine -- design... Soybean meal extrusion; Extrusion food processing technology; Kalyan 3 phase maize puff making machine, capacity: 100 kg/ ... Fortified rice extrusion line; Fortified rice kernels lentils frk line, normal pp

.jpg)

Jan 25, 2018 · PP extruder. for PET for PC single-screw. Output: 0 kg/h - 2,000 kg/h. Screw diameter: 30 mm - 250 mm. One of the core elements of any extrusion system is and remains the extruder itself. Right from the start, the emphasis at BREYER is on quality and sophisticated technology.

.jpg)

The system can be cleaned easily and without leaving residue according to common procedures in the food industry Maximum-effective support from highly qualified process experts Support for process development, scale-up and other procedural challenges

.jpg)

The Thermal Twin's creative screw geometry, along with an innovative method of high steam injection, allow recipes to be cooked more gently - in a thermal manner – as opposed to an aggressive high shear method found in traditional extruders.

.jpg)

Throughput: Typically 400-450 kg/hr, dependant on the product being extruded. Typical products (food): Ready -to-eat breakfast cereals, pre-cooked maize products, textured soy products, expanded snacks. Typical products (feed): Pet food, aquaculture feed, pet treats. Main Motor: 55 kW AC (ABB) Screw Speed: 500RPM standard, can be varied if required

.jpg)

Global Leader in Extrusion Cooking Systems Complete process solutions for plant-based proteins, pet foods, and aquatic feed. Food Textured vegetable proteins, structured meat analogues, ingredients, protein crisps, breadings, RTE cereals, snacks, hybrid products, and many more. Pet Food Traditional kibble, semi-moist, high fresh meat inclusion

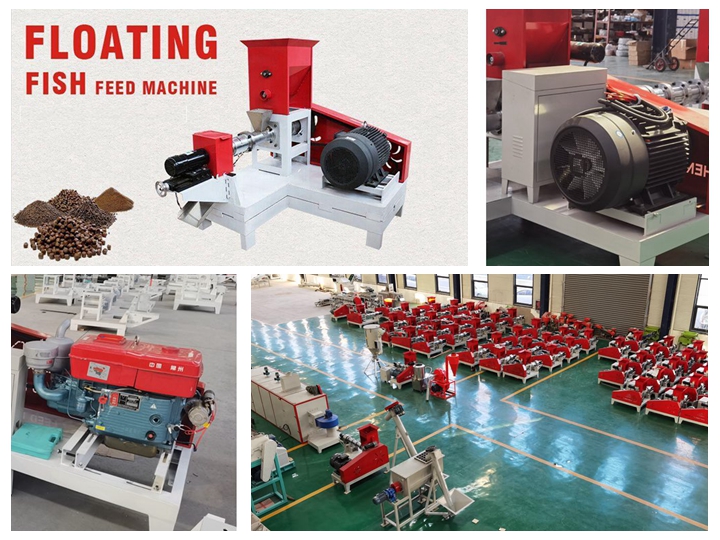

Jun 22, 2022 · There are two types of fish / pet food processing extruder: wet-type and dry-type. Wet type extruder is designed with a boiler which can produce steam throughout. widely used to produce all types of feed for aquatic fish (catfish, crabs. 900kg/h twin screw extruder machine Feed size 8 mm in gujarat

Food Extruder. TVP(textured Vegetable Protein) is a kind of protein product rich in high protein and with muscle fiber structure produced by using low-temperature soybean meal, soybean protein isolate and grain protein as the main raw materials. The application of TVP products in meat products such as tribute balls, lion heads, sausage

.jpg)

Figure 1: End view HP and MAXX screw element geometries. Experimental Data Case Study #1: Comparing twin screw extruders with 1.55/1 and 1.66/1 OD/ID ratios: Previous experimental data was generated comparing 1.5/1 OD/ID and 1.66/1 OD/ID model TSE’s. Process sections were interchangeable and mated to the same gearbox.