.jpg)

The RICHI 10-12t/h floating fish food factory is suitable for the production of floating fish feed, feed for suckling pigs and young pets, puffed soybean meal, and can also be processed to produce livestock feed, and can be used for preprocessing of beans in the oil industry. After being put into production by many users, the response has been

.jpg)

Set up a Pet Food & Fish Feed Production Line. ABC machinery is a fish feed extruder machine manufacturer that specializes in the sinking fish feed, slow-sinking fish feed and floating fish feed processing technology. While improving the digestibility of the final feed for higher conversion, our fish feed machine is very economical.

.jpg)

The RCPH120*2 extruder machine for fish feed is mainly used for the 1.5-2t/h production and processing of various floating aquatic feeds. The new type conditioner can soften material fibers, improve gelatinization degree, reduce power consumption and increase production capacity. Main power: 75kw.

pet food Controlled density according to bag sizes Variety of shapes and sizes Optimal crispness and texture Even uniformity Unique digestibility and palatability High-performance aquatic feed Fast sinking Slow sinking Floating Low or high oil content Size Ø 0,6 - 40 mm High FCR (Feed Conversion Rate) Optimal cost efficiency Fast sinking, slow

.jpg)

Oct 11, 2018 · It is entirely feasible for an extruder to produce floating feed, sinking feed and slow sinking feed by density control; that is more conducive to different fish species. 7.Fine mechanical resistance Feed made using extrusion technology is more resistant to mechanical durability and produces fewer fines in the finished feed during transportation.

.jpg)

Jul 27, 2021 · In order to support provide a balanced and stable feeding for the farmed fish, many producers have shifted to manufactured pellets. Based on the behaviour in the water, fish feed can be divided into floating feed, slow-sinking feed, and sinking feed. IDAH offers you extrusion and pellet mill to produce high quality fish feed.

.jpg)

Aquatic Feed Floating, sinking, slow-sinking feeds, Recirculating Aquaculture System (RAS) feeds, and a wide variety of specialty feeds; Industrial With Wenger systems, you can create new products for industrial or consumer applications. Whatever idea you're thinking about, Wenger can help. Extruders & Dryers. Extruders. Magnum ST Series

.jpg)

Oct 15, 2018 · Application of Wet Fish Feed Extruder. Pellet size: 1-15mm, mini pallet size 0.9mm. Produce floating fish feed, slow-sinking fish feed. Using different molds, can also produce pet food, like dog, cat food and also animal poultry feeds. The wet extruder is used for extrusion of full fat soybean, corn, piglet, soybean meal, cotton seed meal, rice

.jpg)

Floating aquatic feed is suitable for Tilapia feed, Crucian feed, Ranidae feed, Weever feed etc., and sinking aquatic feed for Siganus Guttatus feed, etc. The nutrient components in fish feed mainly consists of protein, starch (sinking aquafeed consists more than 10% and floating aquafeed consists more than 20%), crude fat, raw fiber, crude ash

.jpg)

Aquatic Feed Floating, sinking, slow-sinking feeds, Recirculating Aquaculture System (RAS) feeds, and a wide variety of specialty feeds; Industrial With Wenger systems, you can create new products for industrial or consumer applications. Whatever idea you're thinking about, Wenger can help. Extruders & Dryers. Extruders. Magnum ST Series

The fish feed extrusion process consists of several steps: Ingredient Selection: The first step involves sourcing the best quality raw materials like fishmeal, grains, and oils. Grinding: The ingredients are then finely ground to ensure uniformity. Mixing: Ground ingredients are mixed together in a feed mixer machine.

.jpg)

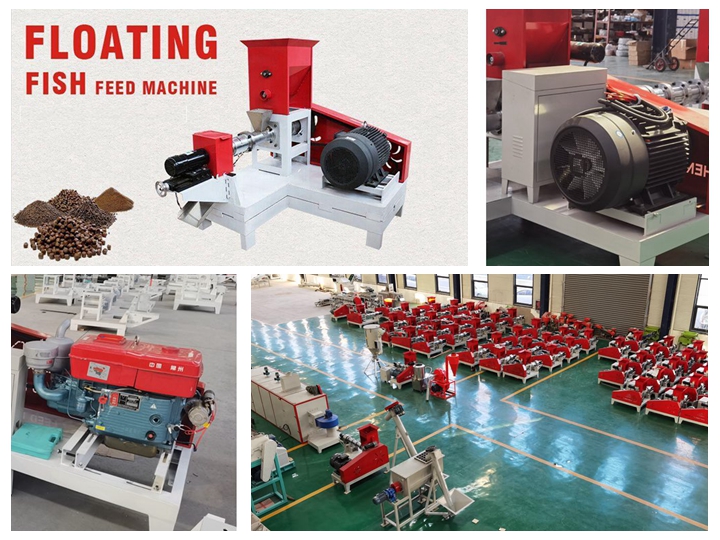

This floating fish feed extruder machine, also called floating fish feed pellet mill, is mainly utilized for making floating fish feed pellets or sinking, slow sinking fish feed for catfish, aquarium fish, shrimp, tilapia, red or black porgy, rainbow trout, carp; it can also be pet food extruder for making pet food for dog and cat.

ADVANCED FEED PRODUCTION TECHNOLOGY. E X TR U D E RS. vanced single-screw and twin-screw extrusion conceptANDRITZ extruders provide the latest technology for production of the most demanding ex. pet food industries.ANDRITZ SINGLE-SCREW EXTRUDERSThe ANDRITZ single-screw extruder represents state-of-the art technology, ensu.

.jpg)

The formulation of sinking fish feed plays a vital role in the health and growth of the fish. Organic ingredients and the right Fish Feed Pellet Size contribute to the feed’s efficiency.The process of sinking fish feed formulation is a sophisticated and critical phase that ensures the nutritional needs of different fish species are met.

Company Introduction: Liyang Weifeng Equipment Co., Ltd. is a professional manufacturer specialized in developing, producing and marketing top-calss Bio-energy equipment and feed machinery system. Now we are focusing our attention on Biomass fuel pellet mill( raw material can be wood, sawdust, rice husk, sunflower stalk, straw etc. ), Wood