.jpg)

There are two major types of extruders; single and twin screw (co-rotating and counter rotating). These come with a wide range of screw diameters ( D ), lengths ( L ), and designs. The single screw and co-rotating twin screw are inherently axially open-channel extruders. They can be regarded as drag flow pumps.

.jpg)

Technical Features Of Wet Type Fish Feed Extruder Machine. 1. The wet fish extruder machine has stronger applicability, low running cost, use differential diameter conditioner, the longest conditioning time is up to 180 seconds, meanwhile conditioning treatment can add into steam and water, increasing materials humidity degree to 25-30%, ensure.

.jpg)

Extruder machine|Large,middle,small feed extruder machine Henan Doing Mechanical Equipment Co.,Ltd Specialized in feed machinery & biomass machinery since 1992.Small Extruders • Email : sale@limamachinery.com

.jpg)

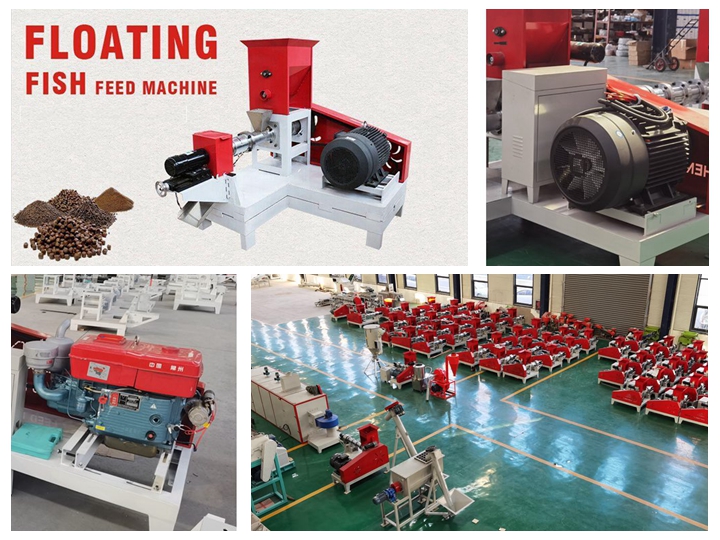

700-800kg/h Fish Feed Pellet Machine by Electric Engine 700-800kg/h Fish Feed Pellet Machine by Electric Engine Floating Fish Feed Machine Prices Machine size (mm):1400*1030*1200 Email: sale@limamachinery.com

.jpg)

Feed Extruder. The nutritional ingredient preservation rate and digestibility of the products produced by the extruder were significantly improved for pet feed, aquatic feed, animal feed,etc. Type: SPH series Raw Material Extruder (wet type) Capac. Type: SPH series Raw Materials Extruder (dry type) Capa. Type: SPH series Fish Feed

.jpg)

300-400kg/h Floating Fish Feed Pellet Extruder Feed Pellet Making 300-400kg/h Floating Fish Feed Pellet Extruder Feed Pellet Making Machine Price Model :LM90 Capacity (kg/h):300.

2020/11/04 · Frank Garczynski says: November 6, 2020 at 7:46 am. A high capacity extruder runs 15-20 tons per hour, max. Using 700+ connected horsepower. Prohibitive manufacturing costs for integrated feeding on such low capacity. That’s why pet food can afford this, with their stratospheric margins. We use standard double pellet conditioners with 60

.jpg)

Dry type fish feed extruder is widely used for producing variety materials into high-grade aquatic feed pellets for fish, catfish, shrimps, crab etc. The final products have unique shape and good taste, high nutrition and smooth textures.

.jpg)

40-4000kg/H Dry Type Floating Fish Food Feed Extruder Machine Pet food extruder machine is used for processing for dogs and cats (pet food), birds, piglets, frogs, sinking and floating

.jpg)

Price of Fish Feed Pellet Production Machine in Nigeria. For example, we provides wet type fish feed extruder to Nigeria at the prices from US$4 900 to US$34 000, depending on what production capacity the customers choose. Similarly, the prices of dry type fish feed extruder for Nigeria are lower, which can be provided from US$2 700 to US$29.

2017/09/16 · Mini Floating Fish Feed Machine-30 kg/h The mini extruder is specially-designed for small scale fish farming industry with affordable price. It makes producing fish food at farmers’ own farm come true. It takes cost

2020/12/21 · Annual Feed Strategy World’s Top Feed Companies survey Feed Strategy World’s Top Feed Companies edition includes rankings of the feed producing companies throughout the world. Additional data sets in the 2020 issue include top feed companies’ tonnage by region, number of companies by region and companies to watch that are nearing qualification for the

.jpg)

2016/06/10 · Hydrostable, extruded shrimp feeds. This last statement is important as it relates to water stability of shrimp feeds. The target is to produce shrimp feeds that can absorb water, becoming soft and pliable, but that do not break down when submerged. In reality, a shrimp can eat a softer pellet better than it can consume a hard one.

.jpg)

Fish Feed Pellet Extruder Model: DGP & DSP Capacity: 0.03-4t/h DSP Wet Type Fish Feed Extruder Model: DSP Series Capacity: 0.18-4t/h DGP Dry Type Fish Feed Extruder Model: DGP Series Capacity: 300kg/h - 2t/h

.jpg)

2022/05/30 · The new extruder features AMANDUS KAHL stop bolt technology for ideal mixing and venting in the first cylinder section. Special process sections for compaction, cooking and kneading provide a high degree of flexibility and a wide range of setting options for processing feed. Exchangeable screw elements ensure perfect adaptation to different