Specialty/niche twin screw extruders: These designs account for less than 5% of the current twin screw overall market and include: Counterrotating non-intermeshing (CRNI) twin-screw extruder: As the name implies, has non-intermeshing screws. The screws and barrels are modular. The design of each screw

May 13, 2013 · This is an excerpt from Paulson Training Program's interactive video course titled "Compounding With The Twin Screw Extruder". This video clip is from Lesson

.jpg)

Jan 1, 2020 · The extruder motors typically have a higher shaft speed than that of the extruder screw shaft. The motor speed ranges from 1100 to 2000 RPM but most commonly is at ~ 1750 RPM. Most extruders’ screw shaft speed is up to 600 RPM. Thus, a speed reduction ratio device is needed between the motor shaft and the screw shaft.

.jpg)

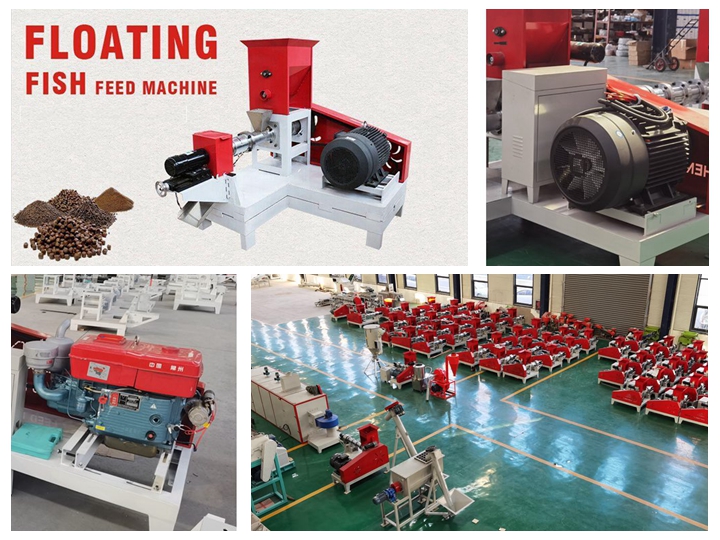

Fish Feed Extruder for Tilapia Floating Fish Feed Twin Screw Extruder Processing Line Fish Feed Making Machine. new. Manufacturer: JZ; Looking For Agent To Get Big Win-Win And Share Markets Together, U Can Get: 1. China 20years top professional manufacturer technology and VIP service support. 2. Top quality, with longer quality warranty. 3. Very

.jpg)

Sep 22, 2023 · Home - Industrial Extrusion. CALL US ON UK +44 1733 283000 US +1 616 784 3111. Careers. UK bpltd@bakerperkins.com. US bpinc@bakerperkins.com. UK +44 1733 283000. US +1 616 784 3111. News Baker Perkins win in two categories at Peterborough Telegraph Apprenticeship Awards 2023 View ». EN.

.jpg)

Sep 22, 2023 · The SBX Master™ twin-screw extruder range is engineered to maximise versatility and outputs while providing high levels of food and operator safety. Flexibility for growth Additional units can be incorporated into a basic line to build capability and flexibility allowing companies to bring new, high-value products to market quickly and effectively.

.jpg)

1 Set (MOQ) Top 1 Planetary Extruder Manufacturer in China with 29 years of experience! Advantages of HT Planetary Extruder 1. Best plasticizing effect 2. Long life of planetary screws Beijing Huatengzhengcheng Industry and Trade Co., Ltd. Inquiry Basket. 1 / 6. Professional Manufacturer of Twins Screw Compounding Extruder for Any Plastic.

.jpg)

The single screw extruder is the basic model and works by feeding plastic material (granules, flakes, or powder) from a hopper into the extruder barrel. The material is gradually melted by a single screw and an agitated mixture produced by heaters designed along the feed tube. The molten plastic polymer is then extruded from the die to produce

.jpg)

Apr 30, 2020 · A twin-screw extruder has about three times more material output than a single-screw extruder of a similar size and screw speed . Theoretically, the material flow process can be divided into four sections: (a) feeding of the extruder, (b) transport of mass, (c) flow through the die, and (d) exit from the die and subsequent downstream processing.

.jpeg)

Twin Screw Extruder process developed by twin screw extruder manufacturers more then 30 years, enables the continuous production of highly homogeneous and finely structured products, using bio-sourced or synthetic raw materials. It is used to produce a wide range of Food & Feed products, our multifunctional food extruder machine offer flexible

.jpg)

Jul 1, 2017 · Single-screw extruders utilize one screw and twin-screw extruders use two intermeshing screws. Both styles of extruders operate in a similar manner, providing transport, compression, mixing, cooking, shearing, heating, cooling, and shaping of raw material final products. As extrusion was introduced to various industries, it has replaced less

.jpg)

Equipment Design. Extruders have three key components: The hopper, where the material is fed to the extruder. The screw runs along the length of the machine. The optional static mixers at the end. Single screw extruders rely on the friction between the material and the barrel for flow: the greater the friction, the slower the flow.

.jpg)

Aug 13, 2016 · Three-zone principle. The screw starts with a feed zone: Constant depth, takes up 15 to 30% of length. In the middle is the compression zone, walls close in on the melt/pellet mix, drive air backward and make up for slipping and rolling of pellets in the feed zone. This zone contains the “barrier” of barrier screws: A long double-channel

.jpg)

This twin-screw extruder is the ideal companion to recipes with a large volume of meat slurries or fresh meat. The New ANDRITZ twin screw extruder ensures complete utilization of starch and ensures total material discharge, for the best hygienic conditions as well as quick recipe changes.

.jpg)

1. Single Screw Extruder & Twin Screw Extruder. Single Screw Extruder. There are two types of extruders which are mostly know. First is the single and other is the twin screw extruder. Twin screw extruders are those which offer counter rotating. These come along with a very wide range of screw dimensions and designs.