.jpg)

Nov 30, 2023 · November 30, 2023. 6:36 am. Jasonxue. Twin screw extruders and compounding machines are the center of many industrial processes. These machines use two screws that interlock with each other and are placed within the same cylinder to blend, compound or melt materials. What makes them different from other designs is their ability to control such

.jpg)

You can find an electric meat grinder of different power capacities such as food grinder machine 1500W, food grinder machine and food grinder machine 2000W. Order Professional Meat Grinder Now Grind your own fresh meat in minutes with Jumia Ghana that provides you with the best meat grinder in town.

.jpg)

Mar 4, 2006 · kW=motor rating on the HSEI twin-screw extruder. For example: If a HSEI twin-screw extruder with a 60-mm screw diameter has a torque rating of 2800 N-m and uses a 200-kW motor if geared for 600 rpm, then a 400-kW motor would be specified at 1200 rpm as indicated below: 2800 = (9550 x 200)/600. 2800 = (9550 x 400)/1200.

.jpg)

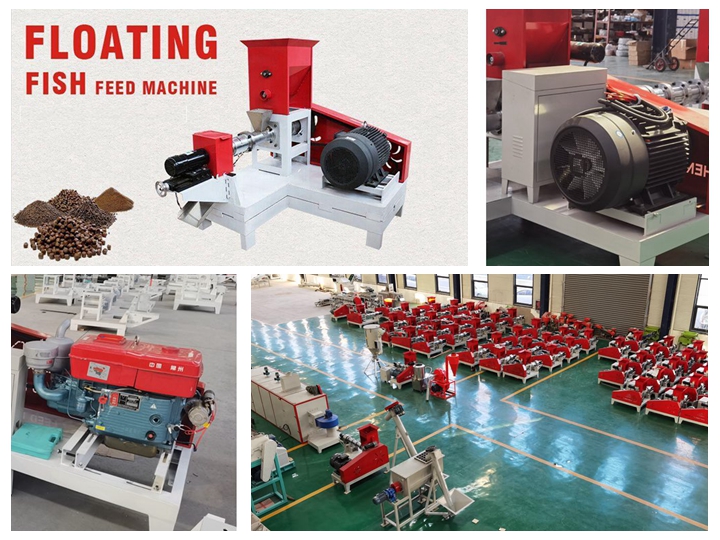

Wet Type Fish Feed Extruder Machine - Lima Fish Feed MachineThe wet type fish feed extruder machine is mainly used to produce high-quality aquatic feed such as fish, shrimp, crab, +8619337889051 Email: lima37@limamachinery-Lima

.jpg)

large scale feed extruder machine crab Ecuador-Feed Pelleting. wet-way fish feed extruder machine Ecuador for new designFactory Outlet motor-type floating fish feed production linefish feed making machine is widely used in family and small sc Tel:8619337889051 Email:sale@limamachinery-Lima. Get Price.

.jpg)

Ultra deep channel type twin screw extruder DS series; Machine Composition. We can provide system engineering for ancillary equipment such as a feeder that quantitatively feeds raw materials into the twin-screw kneading extruder, a cooling water tank that cools the extruded strands, and a pelletizer that cuts the strands.

.jpg)

Jan 1, 2017 · While single-screw extrusion (SSE) is a mechanically simple and low-cost processing option, twin-screw extrusion (TSE) has been used extensively for mixing, compounding, or agglomerating a variety of ingredients to produce a wider range of products. Download : Download full-size image. Figure 31.1. Types of extruders.

.jpg)

All B&P Littleford twin-screw extruders – the BP, CT, and Specialty - have two intermeshing, co-rotating screws mounted on splined shafts in a closed barrel. The screws are tight and self-wiping, which eliminates stagnant zones over the entire length of the process section. This results in high efficiency and perfect self-cleaning.

.jpg)

Jieya is a trailblazer in the extrusion technology industry, harnessing over 20 years of experience to provide innovative machines and systems that enhance productivity and competitiveness. Our solutions are designed to maximize cost savings and efficiency, enabling our customers to achieve fully automatic production.

.jpg)

30200525High moisture food extrusion - Agricultural Research Servicehigh moisture food extrusion has been reviewed. Wet extrusion applications utilise twin screw extruders due to t Email : lima37@limamachinery.com

.jpg)

During twin screw extrusion raw material is conveyed, compressed, degassed, plasticated, sheared, kneaded, fused at optimum level and homogenized before it enters the die. Parallel Counter-rotating Twin Screw Extruder, like the one manufactured in Bausano, are the better solution for working for example PVC+100 p.h.r CaCO3.

Jan 17, 2024 · A plastic extruder machine is a piece of industrial equipment used in the manufacturing process of plastic products. It works by melting raw plastic material and shaping it into a continuous profile, such as pipes, tubing, sheets, films, or other complex shapes. The process involves feeding plastic pellets, granules, or sometimes powder into

Twin screw extruders are available for research and development purposes to process as little as a 50 gm batch, and for full-scale production at more than 50,000+ kgs/hr. The length of any TSE process section, referred to as the L/D ratio, is the length of the screws to the screw diameter.

.jpg)

The Thermo Scientific Process 16 Twin-Screw Extruder is a highly modular extrusion system with a wide range of options and accessories designed to meet your processing requirements. Fast and reliable material development for the polymer, food, and pharmaceutical industries. Use as little as 0.4 kg of material or go up to 18 kg/h to optimize

.jpg)

small crab pellet making machine in Zambia-limafishfeedextrudersmall-scale-crab-feedsmall scale crab feed pelleting machine in Zambia-Feed For a cheap, easy-to-operate, yet reliab Tel:8619337889051 E-mail: lima37@limamachinery.com