.jpg)

The production of aquatic feed often uses a horizontal double-shaft paddle high-efficiency feed mixing machine or a double-shaft double-screw mixer. The former has a mixing time of 2 to 3 minutes and a CV of less than 5%; the latter has a mixing time of 5 to 6 minutes and a CV of 5% to 6%. . 4-5T/H floating fish feed plant often uses two mixing

.jpg)

How to Produce Floating Fish Feed. After choosing a suitable formulation, the next crucial thing is mastering the production process of floating fish feed. Mixing & grinding: The main raw materials of floating fish feed should be mixed and crushed before making pellets, so FANWAY recommends the related professional equipment – fish feed mixer

.jpg)

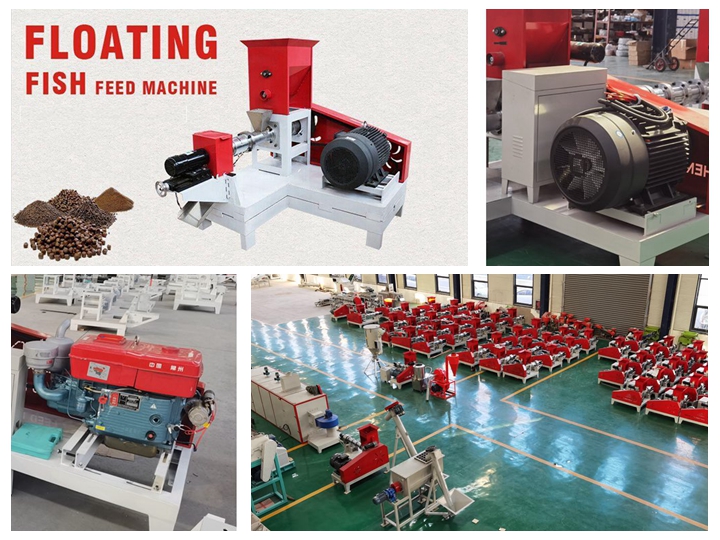

Floating fish feed extruder machine is a key feed making machine used in the floating fish feed mills and aquaculture farms.

.jpg)

Price: USD9000 to USD25000 PER SET. Supply Ability: 5 SETS PER MONTHLY. Description. Floating fish feed extruder is a machine used in aquaculture and fish farming to produce floating fish feed pellets.

.jpg)

03 8-10T/H Fish Feed System Can Be Customized. ① The entire 8-10t/h fish feed making plant adopts a modular design, which can be customized according to the actual needs of customers, formula, plant structure, floor space and other requirements; ② 8-10T/H fish feed processing plants with various forms (extruded pellet, powder, pelletized

.jpg)

Floating fish feed extruder for sale,floating fish feed . Fish feed extruder, also called floating fish feed machine, is widely used for produce high-grade aquatic feed pellets for farming fish, catfish, shrimp, crab. Our company offer you two kinds of floating fish feed extruder, divided into AQUA feed extruder,and dry extruder. Small Floating

Raw Material Preparation. The first step is to gather the necessary ingredients for the feed formulation. Common ingredients for fish feed pellet making include fishmeal, soybean meal, wheat flour, fish oil, vitamins, and minerals. These ingredients are mixed in specific proportions to ensure a balanced diet for the fish.

.jpg)

2.4 Processing line machines pictures 2.4.1 Series extruders 2.4.2 Series dryers 3. Expanded fish feed samples introduction In order to meet modern fish farms development, most of modern fish feed is made by twin-screw (or single screw) extrusion production line, which is called expanded, extruded or puffed fish feed.

.jpg)

There are two types of fish feed extruding machine. One is dry type fish feed machine, the other is wet type fish feed machine. Learn about the main structure of our flaoting fish feed extrduder machine for sale: lt has enough space for large quantities of feed to ensure a stable supply to the extruder. To keep the flow stable safe for the extrudin See full list on abcmach.com The feed drifts down the feeder as pressure on the feed creates a uniform input. The material is squeezed with more pressure and friction. You can use electricity in the compression chamber by connecting the electric sheet to increase the heat for an easier extrusion. This chamber is suitable for softening the hardest fish feed raw materials making... See full list on abcmach.com Make Expanded Fish Feed Pellets Extruded fish feed is designed according to your specific feed portion and style. With the increased cost of feed and the demand for healthier fish, extruded fish feed is enormously beneficial. 1. More palatable: With the pressure applied at extrusion, the feed is made softer and digestible. The feed also retains all... See full list on abcmach.com

.jpg)

Moreover, you can change extrusion degree to influence floating time. The fish pellet made by the machine can float on water more than 24 hours. Gelatinization degree can reach 90%. Brand Name:Loyal. Model Number:PFE-65-1 PFE-70-1 PFE-85-1 PFE-90-1 Place of Origin:Shandong, China.

.jpg)

Understanding global trends in fish feed extrusion technology can offer insights into the features that might soon become standard in Nigeria. This knowledge helps you future-proof your investment. 2. Assess Machine Capacity and Efficiency. Higher capacity fish feed making machine in Nigeria tend to cost more. Determine the scale of your

.jpg)

RICHI specializes in twin screw floating fish pellet machine for sale, our extruder is used to produce aqua and pet extruded feed pellets.

.jpg)

2. Extruding chamber: it consists of a screw, a barrel, a template, a clamp and so on. The screw, and barrel are piecewise combined, so the degree of compression can be adjusted in accordance with the type and requirements of extruded feed, in order to change the expansion of the extruded feed. 3. The expansion mechanism is divided into 3

.jpg)

Processing and Application of Floating and Sinking Fish Feed. With the further development of the fish farming industry, extruded fish feeds have obtained more and more wide applications in virtue of unique advantages including high nutrients, good palatability, strong digestibility, and so on. As a new technology to produce feed, extrusion

.jpg)

4 days ago · Pellet mills are used for making sinking feeds like that for shrimp and trout. It is also utilized where the fat requirements are below 12 percent. Extrusion process can make feeds that are both sinking and floating. The ability to control the floatation of feeds makes extrusion process more versatile.