.jpg)

Oct 1, 2001 · Extruded product bulk density first decreases and then increases as extrusion moisture decreases. (Fig. 2). Fig. 2: Effect of extrusion moisture on bulk density. Vented extruder barrel. Extruder barrels can be configured to include an atmospheric vent to permit reduction in extrusion pressures to cool and densify the extrudate.

To increase the efficiency of the grinding process: e.g. high oil content ingredient such as fish meal, full fat soybean meal, • would, e +8619337889075 lima38@limamachinery.com

.jpg)

In an extrusion process with high moisture over 35 percent, temperatures exceeding 140 degrees C, and high pressure and shear, globular proteins like soybean meal and wheat gluten can be dispersed to form a continuous melt.

.jpg)

Complete Extruded Dry Pet Food, Wet Pet Food, Fish Food or Pet Treat Systems Capability. Whether manufacturing in a batch process or in higher volumes via continuous methods, Coperion and Coperion K-Tron feeders and material handling equipment as well as Coperion high efficiency extruders are used throughout the dry pet food, wet pet food and pet treat as well as aquatic fish feed

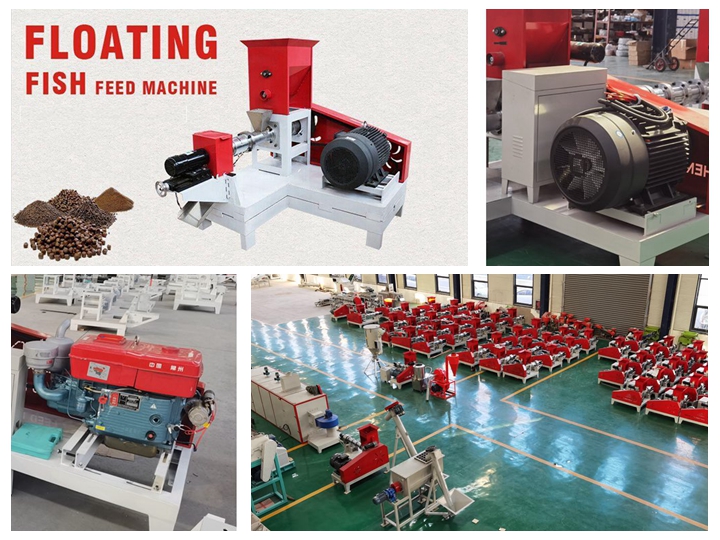

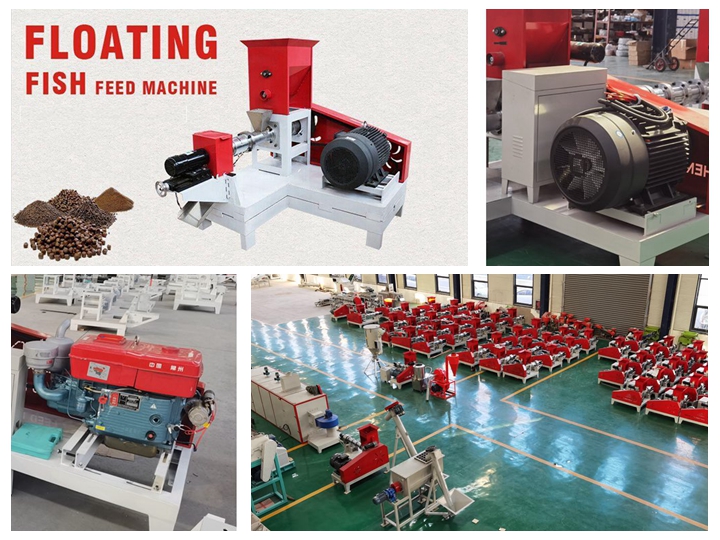

6. Fish Food Processing Line. The Fish Food Processing Line is a complete set of equipments for the extrusion of fish and other aquatic feed products. The cutting cutter and host use frequency conversion speed control. The main gear box is equipped with a lubrication system and gear oil pump to maintain a good performance.

.jpg)

Clextral extrusion systems efficiently produce high-energy feed with a precise balance of proteins, oils and carbohydrates, processed for optimum digestibility. Extruded feeds are produced to match fish feeding habits (floating, neutral buoyancy or sinking) to energize feeding and reduce waste.

.jpg)

3 parts mechanism. Feeding section: This section, with a larger pitch, mainly conveys and compresses materials to fill the spiral groove with feed. Compression section: The spiral groove becomes shallower along the pushing direction to compress the material.

.jpg)

May 17, 2023 · Mini Fish Feed Extruder Machines . Mini fish feed extruder machines are lower performances than regular fish feed extruder machines. They’re designed for small-scale fish farmers who don’t need large product volumes. And it’s cheaper and easier to operate. Wet Fish Feed Extruder. This machine has a high sales volume in Nigeria.

.jpg)

ZSK Food Extruders have higher capacities than competitive products within a lower overall space footprint and reduced energy profile. This is due to the industry-leading screw speed of 1800 min-1. Coperion’s ZSK Food Extruder in Hybrid Version makes it easy to set up production for both. TVP and HMMA, and switch between the two. ZSK Food

is fitted within a barrel which has the die at the end. This article focuses on the extrusion in food Keywords: Extrusion system, extruded foods, extruder, extrusion cooking Introduction Extrusion is defined as a system of pushing mixed ingredients out through a small opening, [1]. In food extrusion involves the both physical and chemical

.jpg)

Feb 7, 2022 · The development of meat alternatives is a sustainable choice to meet eco-friendly and healthy demands. High-moisture extrusion (HME) technology has been applied to produce the textured plant proteins, which are recognized as meat analogues and have characteristics, nutrition, sensory attributes, and apparent fiber structure similar to animal meat.

.jpg)

Process 11 Twin-Screw Extruder: high moisture meat analog, HMMA, soy protein, pea protein, wheat gluten: Effect of Screw speed, Temperature and Moisture on Physicochemical Properties of Corn Gluten Meal Extrudate: Xu, et al. Eurolab 16 Twin-Screw Extruder: low moisture meat analog, HMMA, soy protein, rice protein, corn gluten

.jpg)

Jan 1, 2014 · Mild extrusion conditions (high moisture content, low residence time, low temperature) improve the nutritional quality, while high extrusion temperatures (200 o C), low moisture contents (<15%

.jpg)

Die size variation also shows high impact on the machine performance, showing highest efficiency of 83% at 10 mm die size and 250 rpm while the floatation rate was 98% at 6mm die size.

1 day ago · In the 1930s, extrusion technology was adopted by the food industry. The extrusion application in foods started in the 1930s with the production of breakfast cereal pellets and dry pasta on single screw extruders (SSE). Dry pet foods were manufactured with extruders in the 1950s.