.jpg)

Hence, you must select a machine that can produce the right type of pellets for your specific fish. for floating pellets, you need floating fish feed extruder, for sinking pellets, you need sinking fish feed machine. Understanding the Manufacturing Process In the fish feed making process, raw materials are first mixed and ground into a fine powder.

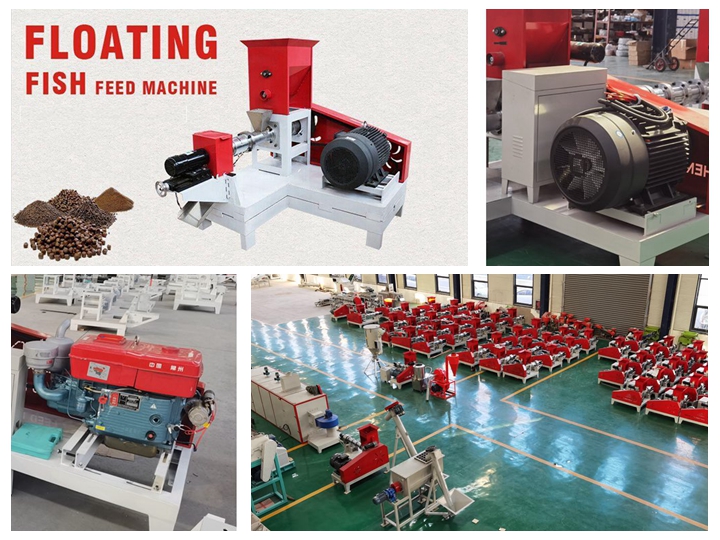

1. Display of the floating fish feed machine. There are various models of our fish food pellet machine, from 40kg/h to 3-4 tons per hour. As for 40kg/h to 300kg/h fish feed extruder, which can be powered by an electric motor or a diesel engine. This machine is very suitable for small and medium fish farms.

.jpg)

The production capacity can be 300kgs/h to max 90 t/h. Richi Machinery focuses on wood pellet plant and wood pellet machine for sale, as a professional wood pellet mill manufacturer, Richi Machinery offers the supply of turnkey wood pelleting plants for the production of pellets including the following steps:

.jpg)

Floating Fish Feed Extruder Machine 3-4T/H. Floating Fish Feed Pellet Making Machine 4-5T/H. Floating Fish Feed Pellet Mill 6-7T/H. Fish Feed Pellet Extruder 8-10T/H. Floating Fish Pellet Machine For Sale 10-12T/H. Sinking Fish Feed Machine. Menu Toggle. Fish Feed Processing Line. Sinking Fish Feed Pellet Mill 0.6-1.2T/H.

.jpg)

All our small scale pellet machine are European standard – CE certified; small feed pellet machines are designed as enclosed houses to cover the motor. This home pellet mill has low consumption, competitive price and cost saving. Both the roller and the flat die are made of alloy metal precision materials, so that the core is wear-resistant

.jpg)

The Fish Pellet Making Machine is engineered to provide quality and quantity output in the form of fish feed. The fish feed in the form of pallet is available in all sizes and dimensions, meeting the requirements of the application area.With unmatched quality and excellent performance of Fish Pellet Making Machine , we have earned huge

.jpg)

good price cow poultry feed pellet machine. $498.00 / set. 1 set (Min Order) CN Anping County Yize Metal Products Co., Ltd. 11YRS. 4.5 (44) | "good service" Animal poultry fish pig cattle cow sheep chicken feed pellet mill making machine small feed pellet machine Malaysia for sale. $345.00-$395.00 / set. 1 set (Min Order) CN Xuchang Jinglai ...

.jpg)

To mix different flour materials together and evenly. 3. Extruding and pelleting. Fish Feed Extruder. To make fish feed pellet, the material is processed by high temperature and pressure and pelletized into round pellets, suitable for feeding fish, we could produce both floating fish feed and sinking fish feed. 4.

.jpg)

Small Animal Pet Catfish Food Making Extruder Floating Fish Feed Pellet Machine: N41,000 – N67,000. Rongchang floating fish feed extruder machine: N615,000 – N700,000. Zhangsheng Fish feed making machine poultry feed wood pellet machine mill: N123,000 – N172,000. 2020 1-2TPH Chicken Cattle Cow rabbit poultry livestock fish sheep goat

structure of pellet cooler. Pellet cooler machines are key equipment in cooling systems in modern pellet production processes. It directly affects the cooling and dehumidification effect of pellet feed and product quality indicators, such as moisture, pulverization rate, etc. The pellet mill cooler is mainly composed of a feeder, a bulk feeder

.jpg)

The 3-4t/h floating fish feed extruder machine with good control performance can effectively guarantee the quality of floating fish extruded pellets, stable and reliable. The new generation of multi-screw coaxial continuous extrusion makes material mature more uniform and discharge smoother.

Our 0.15-60 t/h floating fish feed mill solutions are complete system for producing floating pellets with moderate protein and fat content for feeding warm-water species such as tilapia, eels and catfish. We can help you choose between a single screw and twin screw extrusion process to meet your demands and optimize floating feed production costs.

Floating Fish Feed Pellet Making Machine. RICHI 4-5t/h floating fish feed pellet making machine is a kind of twin-screw feed extruder, mainly used in the production of aquatic feed, pet feed, livestock and poultry extruded feed. Extrusion and puffing is a high-temperature, high-pressure, instantaneous, and ripening process.

Dry (sun or use a dryer) the floating fish feed ingredients to be made into shrimp meal, then grind. Shrimp meal is a source of pigment that enhances the desired color in fish tissue. It is also a secondary source of supplemental protein for fish. Squid meal is made from the visceral parts of squid in canneries, including eggs and testicles.

.jpg)

Oct 14, 2023 · Pellet mills are used for making sinking feeds like that for shrimp and trout. It is also utilized where the fat requirements are below 12 percent. Extrusion process can make feeds that are both sinking and floating. The ability to control the floatation of feeds makes extrusion process more versatile.