.jpg)

Feed Extrusion Plant. Application: Our fish feed machine and feed extrusion plant is widely applied to make floating feed, slow sinking feed and sinking feed ( suitable for feed tilapia, black carp, gurnard, grass carp, bighead, bream, catfish, shrimp and other types of aquatic animals).

.jpg)

Home Floating Fish Feed Machine Menu Toggle Floating Fish Feed Production Line Extruder Machine For Fish Feed 1.5-2T/H Floating Fish Feed Extruder Machine 3-4T/H Floating Fish Feed Pellet Making Machine 5-6T/H Floating Fish Feed Pellet Mill 6-7T/H Fish Feed Pellet Extruder 8-10T/H Sinking Fish Feed Machine Menu Toggle Fish Feed Processing Line

.jpg)

Capacity: 1.5-12 T/H. Twin screw extruder price: 70,000-200,000USD. Capacity: 0.03-4 T/H. Single screw extruder machine: 2800-40000 USD. Small Floating Fish Feed Mill. 1-2T/H Floating Fish Feed Plant. 3-4T/H Floating Fish Feed Line. 5-6T/H Floating Fish Feed Production Line. 7-8T/H Floating Fish Feed Processing Plant.

Size of Feed Pellet: 0.9~15mm. The dry type fish feed extruder is an excellent equipment for those looking to make high-quality fish feed pellets. The dry type fish feed extruder is also at times called the fish feed pellet mill. It is widely used for making aquatic food for fish, shrimp, crabs, and other various types of aquatic species.

.jpg)

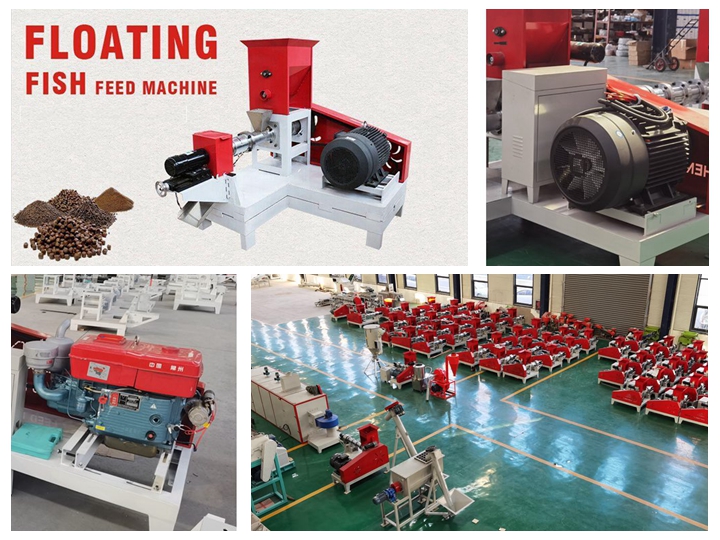

Floating fish feed extruder machine. The floating fish feed extruder machine is mainly used for the production of all kinds of aquatic feed pellets, pets, and other feed pellets such as floating fish feed pellets, shrimp feed pellets, crab feed pellets, and frog feed pellets. Capacity: 1-12T/H; Power: 75-355KW

.jpg)

After the 6t/h fish feed project is completed and put into production, it can form an annual production capacity of 25,000 tons of extruded feed. The products of this 6t/h fish feed plant will be used for freshwater fish and bream feeding. After the project reaches production, it will eventually form an annual output of 25,000 tons of extruded

.jpg)

Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditioning of the raw material. Different molds are available to make pellets of different diameters (0.9-15mm) and shapes.

.jpg)

Production capacity of dry type extruder ranging from 60kg/h (DGP50) to 2t/h (DGP200). Mini fish feed extruder for home use or small scale fish farms to produce floating/sinking pellets for all kinds of aquatic animal.

.jpg)

1. Nutritional content of the feed is guaranteed (you can exactly know the nutritional level of the feed), 2. there is no change according to the season of the year, 3. You can buy it whenever you want from fish feed plants, 4. It is easy to store the feed. Disadvantages; 1. Requires mechanization and automation, 2.

.jpg)

The freshly extruded feed is very fragile, and a reasonable conveying system needs to be installed to transport the feed to minimize product damage, preferably a conveyor belt or an air conveying system. In the 3-4t/h fish feed production line, the drying process is as important as extrusion. The aquatic feed should be dried slowly.

Floating Fish Feed Extruder Introduction Fish feed extruder is primarily used for producing high quality puffing pellets for fishes like catfish, carp, tilapia, salmon, trout, and aquarium fish, etc.

.jpg)

Floating Fish Feed Extruder Machine. As a floating fish feed extruder machine manufacturer, in

.jpg)

03 8-10T/H Fish Feed System Can Be Customized. ① The entire 8-10t/h fish feed making plant adopts a modular design, which can be customized according to the actual needs of customers, formula, plant structure, floor space and other requirements; ② 8-10T/H fish feed processing plants with various forms (extruded pellet, powder, pelletized

.jpg)

20-24T/H floating fish feed production. RICHI 20-24T/H floating fish feed mill plant is factory construction solution for processing extruded feed (floating fish, sunken fish, shrimp, pet feed). Richi Machinery has been focusing on the field of fish feed mill plant for more than 30 years. With a deep understanding of the process flow of the