.jpg)

Jan 6, 2012 · Marel products and solutions help fish processors optimize yield, quality, throughput and other critical factors across the whole value chain. Ranging from individual units for specific processes such as weighing, cutting and bone removal, to complete solutions such as grading, filleting, portion-cutting and slicing lines, our equipment is

.jpg)

May 23, 2022 · small manuel fish feed machine-Lima Fish Feed Making Machine. DGP40 fish feed machine manual small electric floating fish feed extruder machine in nigeria US $1869-$1899 / Set 1 Set (Min. Order) 9 YRS Henan Lima Machinery Equipment Co., Ltd. 97.9% 4.9 (7) "Outstanding service" Contact Supplier 1/2 fish,cat,dog. household manual animal feed

.jpg)

Jun 16, 2023 · Top 10 Seafood Processing Equipment Manufacturers In The World. Find the top 10 seafood processing equipment manufacturers and suppliers. Learn about the factors to consider when choosing the right supplier for your seafood processing needs.

Nov 07, 2019 · Fried Food Processing Fully automatic frying machine. January 4, 2019 and it is also known as fish meat and bone separator machine, fish meat deboner machine, fish Egg & meat proessing machine ... The cashew nut processing plant is also called the cashew nut shelling line and cashew nut peeling line.

.jpg)

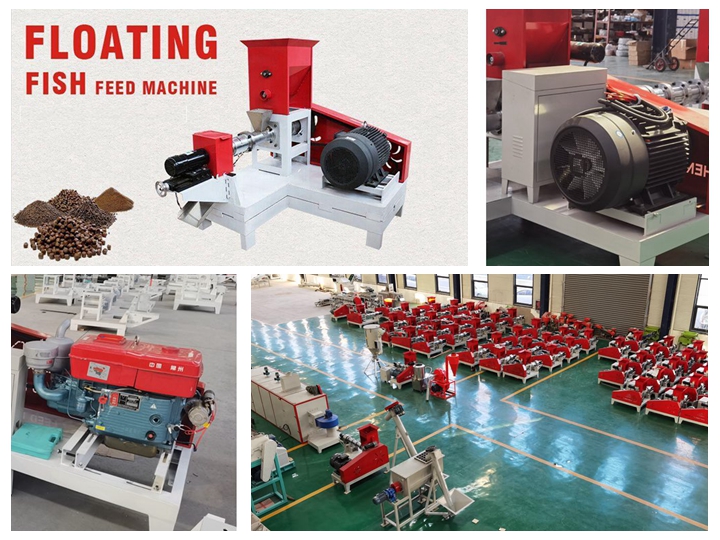

The Complete Floating Fish Feed Production Line is suitable for medium/big farm and commercial fish feed factory, Long working life, make high protein feed, Stable output, high efficiency, continuous work, labor saving, can pack directly, pellet size could be chosen from 0.8-12mm. Capacity: 0.2-10T/H.

.jpg)

Reasonably Priced Fish Feed Pellet Machine in Nigeria. We provides wet type fish feed extruder at the prices from $4,900 to US$34,000, depending on what production capacity the customers choose. Similarly, the prices of dry type extruder are lower, from $2,700 to $29,000 depending on different production capacities.

.jpg)

Fish Feed Production Systems We classified feed types in two groups: 1. Moisture Feeds 2. Dry Feeds (Pellet and Extruder Feeds) Made by non economic fish species The main principle is grind and mix and then feed the fish Most important advantage of the feed is to be cheaper than the other feed types, It does not require any mechanization.

.jpg)

Compared with other animal feed, aquafeed has higher requirements in respect of feed nutrition and physical characteristics (including feed pellet shape, size, density, stability in water and so on), therefore, it is the appropriate feed processing technology and fish food making machines that plays a key role in producing healthy and nutrient aqua feed according to customers specific

Customer Case Of Fish Feed Production Line At 2021. Lyfish-5 Floating Fish Food Making Machine For Sale Pakistan. Small 200kg/h Floating Fish Feed Production Line Moldova. 100-150kg/h Floating Fish Feed Plant Foe Sale Ukraine. Lyfish-50 Small Electric Fish Food Making Machine For Sale Singapore.

.jpg)

We are a professional manufacturer focusing on manufacturing of fish feed pellet machine. Our floating fish feed pellet mill production capacity covers 40kg to 1000kg per hour. In addition to stand-alone machines, we are also good at designing and integrating complete fish food production lines with flexible configurations.

.jpg)

Jul 8, 2023 · Fish processing is an indispensable part of fish food production. It mainly involves de-heading, gutting, filleting, skinning, trimming, and slicing, with the cutting operations holding a critical role. Unfortunately, inefficiency, low quality, and poor safety are the primary problems facing the fish processing industry today, dramatically hindering the automation and intelligence of fish

.jpg)

Fish rendering is the process that converts fish waste into valuable products for animal feed. Waste products come mainly from fish processing plants. Parts of the body that can be processed: heads, particles of flesh, skin, bones, entrails, and liver. During processing, fish by-products are sterilized and dried for final moisture of about 10%.

Use of hygienic wall, floor and drain materials is essential, as is the separation of all contact surfaces to avoid spread. Basic good practice for seafood factory planning includes: Effective drainage for high volume wet processing environment. Positioning drainage away from clean/finished product areas.

.jpg)

Fish Feed Plant Production Process. Generally speaking, fish feed production process flow has several main steps, including procurement of feed ingredients, raw materials grinding, mixing, extruding, drying and automatic weighing and packaging, in tune with scientific and nutrient aquatic feed formulation. Acquisition of feed ingredients.

.jpg)

ANDRITZ designs and manufactures all the key processing technology necessary for complete plant solutions for the aqua feed industry. The fish farming industry is experiencing considerable growth in all regions of the world, creating an ever-increasing demand for high-quality fish feed. The key to successful fish farming is correctly