.jpg)

Insect feed for poultry and fish production in Kenya and Uganda, Grant/Award Number: 107839-001 Abstract A composite blend consisting of sunflower cake, maize germ, wheat bran, fresh water shrimps and cassava flour was extruded using a single-screw extruder to produce expanded fish feed pellets.

.jpg)

Home » Blog » Fish Feed Machines » farthest aqua fish feed formulation extruder (PDF) Extruded Aquaculture Feed: A Review - ResearchGate 2018-2-28·The thermal process during extrusion decreases the antinutritional factors present in legumes or other agro-industrial by-products, such as trypsin inhibitors and lectins.

Common carp - Feed formulation. Diet formulation provides for a balanced mixture of ingredients which support all biological functions such as maintenance, growth, reproduction and health at an acceptable cost (Chiba, 2009). Further general considerations (appropriate physical characteristics, palatability, avoiding antinutritional factors

.jpg)

Apr 1, 2001 · Aquafeeds Extrusion production of aquatic feeds 1 April 2001 Galen J. Rokey Extrusion can provide feeds for species that require higher levels of fat and/or floating characteristics Fig. 1: A variety of feeds can be manufactured with extrusion systems.

.jpg)

Feed accounts for 60–80% of tilapia production costs, and high feed cost and limited feed access are major issues faced by fish farmers. A potential solution is for farmers to produce their own

.jpg)

Feb 20, 2019 · Along with soybean meal and other ingredients such as milk powder, corn flour, eggs, cod liver oil, vitamin mixture containing vitamin B complex and E, agar powder, garlic paste, pepper powder & cumin powder are used. Preparation of feed Soybean meal (80gm) was taken in powder type as principal ingredients.

.jpg)

•1. Nutritional content of the feed is guaranteed (you can exactly know the nutritional level of the feed), •2. there is no change according to the season of the year, •3. You can buy it whenever you want from fish feed plants, •4. It is easy to store the feed.

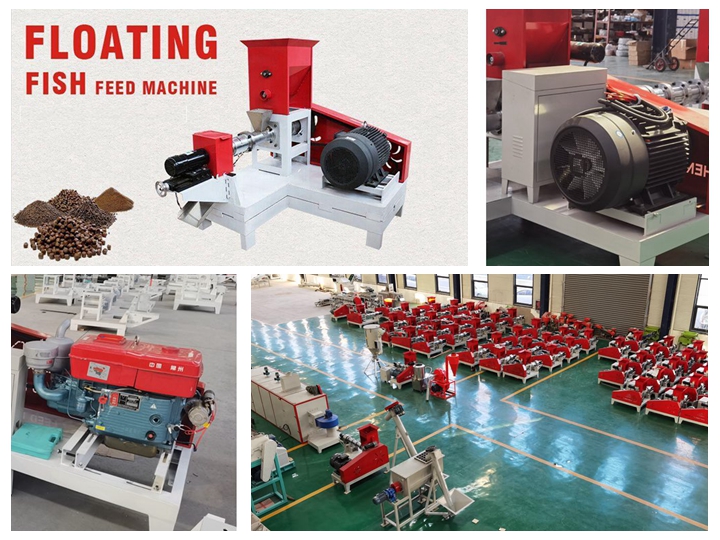

Fish Feed Plant Production Process. Generally speaking, fish feed production process flow has several main steps, including procurement of feed ingredients, raw materials grinding, mixing, extruding, drying and automatic weighing and packaging, in tune with scientific and nutrient aquatic feed formulation. Acquisition of feed ingredients.

.jpg)

fish feed formulation ingredient compositions of catfish feed, tilapia fish feed and other fish feeds, The farmers can adjust different kinds of raw materials according to the their fish. Ideally, fish food should provide the fish with fats (for energy) and amino acids (the building blocks of protein), and fish food (whether flakes or pellets

.jpg)

Oct 15, 2020 · The fish feed mixture is put into the fish feed extruder so that it can be processed into pellets. The size of the pellets will depend on the size of the fish that wants to be feed. Fish Feed Extruder. Dry the Fish Feed Pellets: After granulated mash is formed, it is then dried in a fish feed dryer to reduce the moisture content.

Jul 10, 2021 · Abstract. Feed is one of the major inputs in aquaculture production and there is also an increasing demand for quality feeds. Adoption of appropriate processing technology is an important factor

.jpg)

Jul 27, 2021 · Based on the behavior in the water, the fish feed can be divided into floating feed, slow-sinking feed, and sinking feed. IDAH offers you an extrusion and pellet mill to produce high-quality fish feed. Depending on the types of fish feeds, sinking feeds can be made on both pelleting and extrusion systems. Pellet mills can only make fast sinking

.jpg)

There are two kinds of extruders that might be used in aquafeed production: the single-screw extruder and the twin- screw extruder. Single-screw extruder: As its name implies, a single-screw extruder has only one extruding screw and is of simple structure, so its price is relatively lower.

.jpg)

Apr 1, 2004 · Water-soluble: albumins Soluble in saline solutions: globulins Soluble in 40 percent alcohol: gliadins (part of wheat gluten) Insoluble in 40 percent alcohol: gluten – in (part wheat gluten). During the extrusion process, proteins form a disperse phase within the starch matrix.

.jpg)

Composition of the floating aquatic feed formula: A fish feed floating experimental formula was used in the present study, the composition of the formula were corn flour 28%, wheat flour 18 %,soy bean 25%,fish meal 16%, shrimp meal 10%, premix 2%and fish oil 1%, the particle size of the formula were 0.8mm. Equipment list: