Aug 8, 2019 · 3800. 5.Features. 1). The fish feed pellets can float on water for over 20 hours. And sinking and floating aqua-feed pellets both can be made just by adjusting the feed formulation. 2). Pellet diameter is 0.9mm-15mm by changing the mold. The cutter can cut the pellets into different lengths.

.jpg)

Small Pet Food & Aquatic Feed Pellet Plant ( 100~150kg/h) 1. Crushing Machine 2. baghouse system 3. Mixing Machine 4. Feed Extruder 5. Air Conveyor 6. Belt Dryer 7. Coating Machine. Medium Scale Pet and Fish Pellet Plant ( 200~300kg/h)

.jpg)

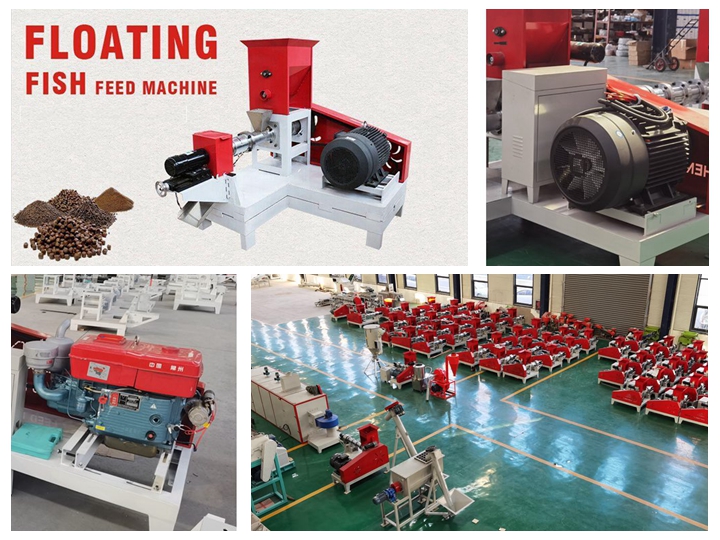

Fish Feed Pellet Line. This full set of fish feed pellet line can be used to produce fish feed pet feed. Low energy consumption, high efficiency. The Feed pellet line can be customized according to your raw materials and the size of fish farms. Floating fish feed pellet machines are with features of less manpower, high efficiency and production

.jpg)

Uniformity: These floating automatic fish feed machine in India ensure that each pellet or feed unit is consistent in size and composition, which is essential for the uniform growth of fish. 4. Flexibility: Many automatic feed making machines in India come with adjustable settings, enabling producers to create different sizes and types of feed

.jpg)

Such as swim bladder issues and puffiness) and also stay clear of aquarium contamination due to excess ammonia. Marine feeds for predators need to contain plant compounds such as spirulina. According to Wikipedia, the source of raw materials fish feed active ingredients for floating fish feed can be acquired from the following methods.

.jpg)

5. Different molds can be chosen to make pellets with different diameters and shapes. 6. Feed pellets diameter is 0.9-15mm. 7. Dry type fish feed extruder does not need the steam boiler, so the dry-type fish feed pellet machine is cheaper and easier to use and operate compared with wet-type pellet machines. Materials for Floating Fish Feed

.jpg)

Oct 11, 2018 · 1. In fish feeding, trash fish and pellet feed are commonly used for fish feeding. Compared with feed pellet, trash fish do not have sufficient nutrients to satisfy the needs of all fish. It may lead to malnutrition which will reduce immunity and increase risks of disease. However, feed pellets produced by fish feed pelletizer for fish diet can

.jpg)

Floating Fish Feed Manufacturing Process. Selection of Raw Material. When selecting raw materials for fish feed processing, remember that the final product must be stable in water. The main nutrients are starch, with 10% to 15% of feed for sunken fish and over 20% of feed for floating fish. The starch content is generally between 5% and 60%.

.jpg)

The fish feed extrusion process consists of several steps: Ingredient Selection: The first step involves sourcing the best quality raw materials like fishmeal, grains, and oils. Grinding: The ingredients are then finely ground to ensure uniformity. Mixing: Ground ingredients are mixed together in a feed mixer machine.

.jpg)

Jul 21, 2020 · Both floating and sinking fish feeds can be produced by our dry type fish feed making machine. It can also be used for making pet food for dog, cat, bird, etc. Advanced and durable

.jpg)

Oct 16, 2018 · The final pellets have unique shape and good taste, high nutrition and smooth textures. For feeds of fish and shrimp, the floating time in water can be adjusted by the extrusion degree adjustment. Feed pellets dia. is 0.9-15mm. We have wet type fish feed extruder and dry type fish feed extruder for your choice.

.jpg)

6. Extrusion with steam preconditioning is known as the wet-type fish feed extruder. The wet-type processing needs a boiler to make steam for the conditioner and ripen the raw material in advance. Dry feed pellets are stable for relatively long periods, for convenient storage and distribution. Note: This floating fish feed machine can only work

.jpg)

Investing in a floating fish feed making machine in Philippines also has economic implications. By controlling the feed production process, you can significantly reduce the operational costs and reliance on external suppliers. This self-sufficiency allows you to dictate quality and pricing, making your aquaculture business more profitable and

⑩ Counter-flow type fish feed cooler ★ Scope of application Mainly used in the process of cooling granular feeds in large and middle sizes feed mills, to easily transport, store, and save, the SKLN contraflow cooler cools granules with a temperature of 60-80 degrees and moisture of 13-15 % from the front dryer down to a little higher than room temperate and moisture 12-13%.

We focus on dry type floating fish feed pellet machine here. The single-screw, dry type machine produces floating fish feed pellets for fish, tilapia, catfish, shrimp, crab, turtle, and goldfish. High temperature in the floating fish feed pellet machine puffs the pellets, allowing them to float for 24 hours. Pellet sizes range from 0.9mm to 15mm.