.jpg)

An alternative solution is using extruder twin screw with temperature and screw speed can be controlled. The objective of the study is developing and assessing of twin screw extruder performance in producing floating fish feed. Principle work of extruders is conveying and mixing feed stuff to the dies under high temperature and pressure.

.jpg)

Wenger has set a new standard for high capacity aquatic feed production via twin screw extrusion. Based on the proven Wenger Magnum twin screw series, the new AquaFlex XT features barrel geometries that allow greater capacities than any other extruder in its class — up to 30 percent compared to previous and competitive aquatic machines.

.jpg)

Watch our product animation to see the NEW ExTS 718 in action and download the datasheets for technical details, sizing, and options. The NEW ExTS 718 Twin-screw Extruder. ANDRITZ Feed & Biofuel A/S. 6705 Esbjerg, Denmark. ANDRITZ Innovative technology for the extrusion of high quality feed pellets.

The twin screw extruder, ExTS 616 & 718, is the ideal solution for the extrusion of pet food with high inclusion rates of meat slurries or fresh meat. The twin screw extruder ensures complete utilization of starch; allowing for higher flexibility in the formulation and enabling a higher feed conversion ratio.

.jpg)

Jun 10, 2016 · Shrimp aquafeeds are traditionally manufactured using a pelleting system with long residence time pre-conditioners. The latter pre-cook the starch portion of the feed to improve its binding ability, to produce a feed with high water stability. But the process of pelleting at moisture levels close to 17 percent is more art than science.

.jpg)

Sep 1, 2008 · The aquafeed manufacturing industry is widely recognised as one of the fastest expanding agricultural industries in the world. Fish meal is the main protein source in aquafeed, but supply is limited, which means that alternative sources need to be used. From a processing point of view extrusion is the most efficient way of turning plant protein into fish feed. Twin screw extruders have a

.jpg)

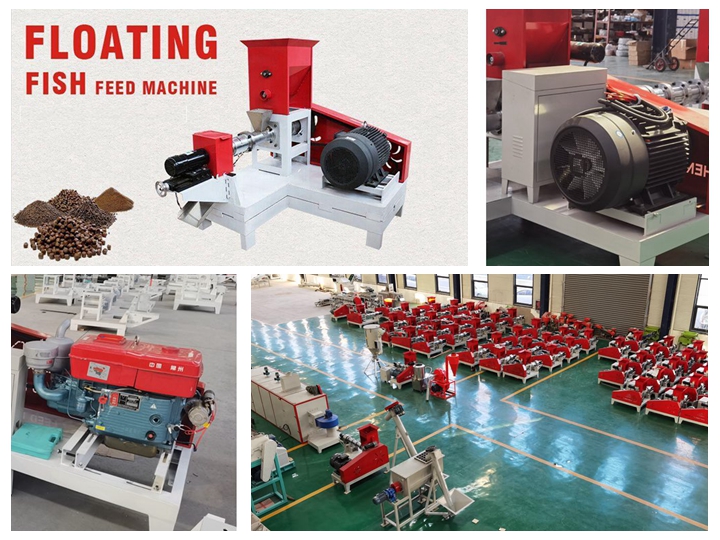

Jul 27, 2021 · IDAH offers you an extrusion and pellet mill to produce high-quality fish feed. Depending on the types of fish feeds, sinking feeds can be made on both pelleting and extrusion systems. Pellet mills can only make fast sinking feeds. For example, milkfish feeds are still common to be made on pelleting lines thanks to advancements in pre

.jpg)

Jan 1, 2008 · Twin-screw extruders have established themselves because they deliver on the requirements of process productivity, flexibility and quality. Their main features are similar to those of single-screw machines, including a feed and conveying section with large pitch screw elements and a compression section where the screw elements are of decreasing

.jpg)

Clextral systems can easily produce high energy feed, allowing a delicate balance of proteins, oils and carbohydrates, processed for total digestibility with no waste. It’s the right formula for high quality products that “turn feed into flesh.” Output range from 25 to 30,000 kg/h. Thanks to twin screw extrusion, high quality

.jpg)

Aug 1, 2022 · The present work aims to develop an innovative twin-screw extrusion process to produce Fish Feed pellets for adult Trout. A twin-screw extruder is in fact capable of ensuring a wide range of functions like starch cooking, which is generally obtained partially in the preconditioner. In this context, the objective of this study is to highlight

.jpg)

new twin-screw extruders for the pet food and aquafeed industries: the ExTS-616 operating in a volume range of 6-10 tons per hour (tph) and the ExTS-718 producing between 10-18 tph – each reflecting the very best innovations in extrusion technology.

Twin Screw Extruder process developed by twin screw extruder manufacturers more then 30 years, enables the continuous production of highly homogeneous and finely structured products, using bio-sourced or synthetic raw materials. It is used to produce a wide range of Food & Feed products, our multifunctional food extruder machine offer flexible

.jpg)

The twin-screw extruder PolyTwinTM completely fulfills process requirements such as high torque, screw speeds and pressure. Thanks to its modular design, this highly sophisticated ma- chine is extremely flexible in application. It can be used to process breakfast cereals, food ingredients, petfood and fish feed for industrial fish farming

.jpg)

1 day ago · The physical feed quality is critical in enabling the feed to provide the desired nutrition and energy to the fish. Some of the common quality issues are feed integrity, non-uniformity of feed sizes, unable to attain the desired level of floatability (in case of floating feeds), dust creation from feeds, oil leakage, rancidity issues, and raw material quality.

Dec 14, 2021 · The shafts of a twin screw extruder can spin in the same direction (co-rotating extruder) or in the opposite direction (counter-rotating extruder). The counter-rotating designs are most often used where high shear areas are desired, as the material is pushed through the space between the two screws when they are in contact.